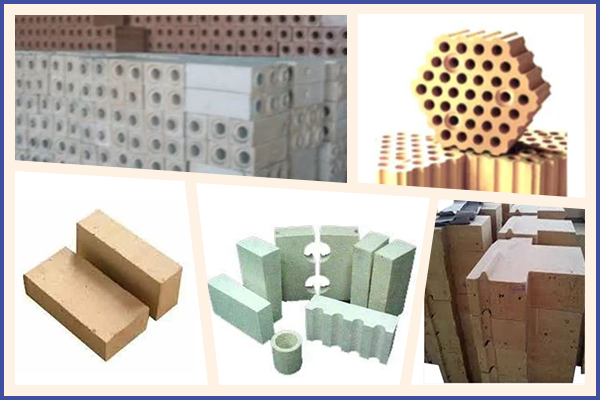

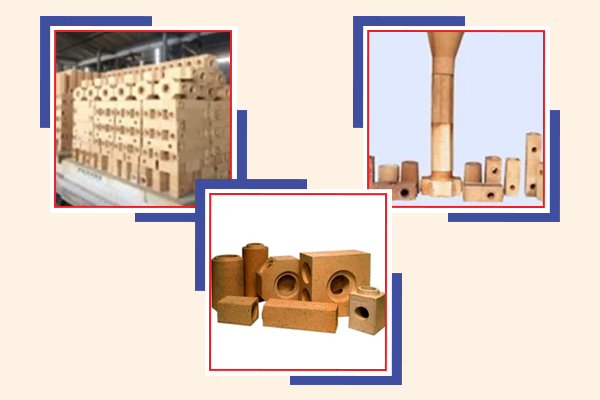

Special Refractory

Special Refractories are principally both oxides and non-oxides and derived composite mixture. They are specially being designed for specific raw materials and mixed as per the design mix to work against high temperature to safeguard the surfaces.

Any refractory material or a product, if it got added value with a mix design or a project-specific shape, with special thermal and physical, is always referred as Specials.

As a material required for specific application against heat, abrasion, load and self-weight, is added with high melting point oxides, high melting point non-oxides, and the derived composite compounds and reinforcing materials.